Everything You Need to Know About Custom Sportswear: A Complete Guide for Brands and Teams

Custom sportswear has become a growing trend among fitness brands, sports teams, and entrepreneurs looking to create unique apparel that reflects their identity. Whether you're a startup, a professional team, or a distributor, understanding the customization process can help you make smarter choices. In this guide, we'll answer the most frequently asked questions about custom sportswear manufacturing.

1. What Is the Process for Customizing Sportswear?

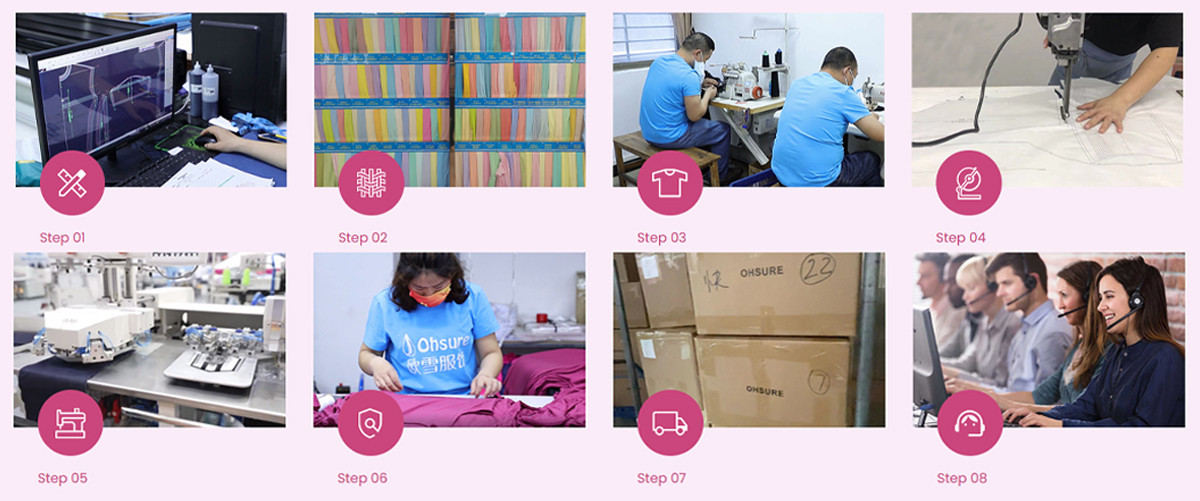

The customization process typically includes the following steps:

• Idea & Concept – You share your design ideas, sketches, or inspiration.

• Design Development – The manufacturer turns your concept into tech packs or mockups.

• Fabric & Material Selection – Choose suitable fabrics based on your sportswear needs.

• Sampling – A sample or prototype is created for review.

• Mass Production – Once the sample is approved, bulk production begins.

• Quality Check & Delivery – Finished products go through inspection before shipping.

2. Where Can I Find a Reliable Custom Sportswear Manufacturer?

You can find manufacturers on platforms like Alibaba, Global Sources, or by searching on Google. Look for:

• Verified businesses with certifications

• Positive reviews and customer feedback

• Experience in OEM/ODM services

• Clear communication and prompt responses

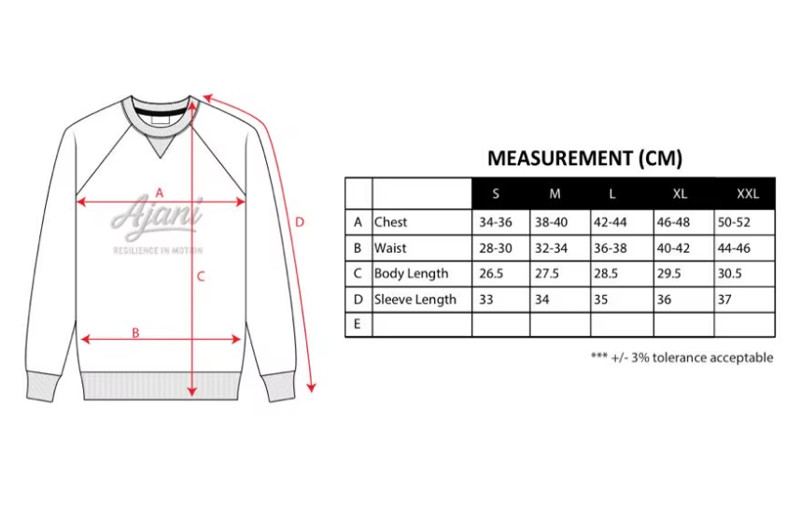

3. What Information Do I Need to Provide to Customize Sportswear?

To get started, prepare the following:

• Product type (e.g., leggings, T-shirts, sports bras)

• Design files or inspiration images

• Logo and branding requirements

• Size chart and quantity per size

• Preferred fabrics and colors

• Special features (pockets, zippers, mesh panels, etc.)

4. What Is the Minimum Order Quantity (MOQ) for Custom Sportswear?

MOQs vary by manufacturer and product type.

• For full customization: 300 pieces per style is common

• For semi-custom or existing designs: 100pcs per color and style, Some manufacturers offer flexible MOQs for startups.

5. How Long Does It Take to Produce Custom Sportswear?

The timeline depends on complexity and order size:

• Sample development: 7–14 days

• Bulk production: 25–35 days after sample approval.

• Add shipping time depending on your location.

6. Can I Add My Own Logo or Branding to Custom Sportswear?

Yes! Most manufacturers support various logo printing options:

HEAT PRESSED LOGO

SILK SCREEN PRINTING

PUFF PRINTING

EMBOSSED LOGO

DIGITAL PRINTING

TOWEL EMBROIDERY

3D RUBBER PRINTING

EMBROIDERY

7. How Is the Price of Custom Sportswear Calculated?

The cost depends on several factors:

When it comes to custom gym wear, the cost can vary significantly based on several key factors. Understanding these elements can help you make informed decisions and plan your budget effectively:

When it comes to custom gym wear, the cost can vary significantly based on several key factors. Understanding these elements can help you make informed decisions and plan your budget effectively:

1. Fabric Type and Quality

The choice of fabric plays a major role in determining the overall cost. High-performance materials such as moisture-wicking, breathable, or eco-friendly fabrics (like recycled polyester or organic cotton) typically come at a higher price point compared to standard materials. Thicker, stretchier, or more durable fabrics also tend to increase the cost.

2. Design Complexity

Custom gym wear can range from simple styles to highly intricate designs. Factors such as the number of panels, types of stitching, presence of mesh inserts, zippers, thumbholes, or contour lines all influence the production complexity and cost. The more complex the design, the more time and labor are required to manufacture it.3. Printing and Decoration Methods

Your choice of branding method—whether it’s screen printing, heat transfer, sublimation, embroidery, silicone printing, or puff printing—can affect the pricing. Some methods are better suited for large volumes or intricate graphics, while others offer more premium results at a higher cost.

4. Order Quantity

In general, the higher the order quantity, the lower the unit price. This is due to economies of scale, as larger orders reduce per-piece production costs. Small batch production is available, but usually comes with higher unit costs due to setup fees and minimum run expenses.

5. Packaging Requirements

Basic packaging (like individual poly bags) is often included, but if you need branded packaging, custom tags, inserts, gift boxes, or eco-friendly alternatives, these will contribute to the overall cost. Custom packaging can help enhance your brand identity but should be factored into your budget.

8. How Do I Choose the Right Fabric for Custom Sportswear?

Selecting the right fabric is a crucial step in creating high-performance and comfortable activewear. The ideal fabric should align with your brand’s purpose, performance expectations, and seasonal needs. Here are some important factors to consider:

1. Purpose of Use

The activity your clothing is intended for will significantly impact your fabric choice:

Yoga: Soft, flexible, and lightweight fabrics that allow for a full range of motion.

Running: Lightweight and breathable fabrics with excellent moisture management.

Gym Workouts: Durable, stretchable materials that withstand repeated movement and friction.

Casual Wear: Comfortable and stylish fabrics suitable for everyday use.

2. Key Functional Features

Choose fabrics with the right performance attributes to enhance comfort and function:

Moisture-Wicking: Keeps sweat away from the skin to help regulate body temperature.

Stretch & Recovery: Ensures a comfortable fit and shape retention during movement.

Breathability: Allows airflow to keep the body cool, especially during intense workouts.

3. Seasonal Suitability

Fabric weight and insulation should match the intended climate or season:

Summer: Opt for lightweight, breathable materials that feel cool against the skin.

Winter: Choose thermal or brushed fabrics that provide warmth without restricting movement.

4. Popular Material Choices

Here are some commonly used materials in activewear manufacturing:

Polyester-Spandex Blends: Popular for their durability, stretch, and moisture-wicking properties.

Nylon: Known for being smooth, strong, and resistant to abrasion.

Bamboo Fabric: A sustainable option that offers softness, breathability, and antibacterial qualities.

Looking for a custom women hoodie manufacturer? We offer oversized heavy fleece sweatshirts with OEM & private label services.

Custom Mens Slim Fit T Shirt Mens Casual Cotton Spandex Slim Fit Short Sleeve T-Shirts Crew Neck Soft Breathable Fitted Tees OEM Factory in China

Custom Oversize Zipper Up Sweatshirt Sweatshirts manufacturer Super soft cotton spandex fleece Women Sweatshirt Supplier

Custom Stylish Gym Bra Women's Sexy Cross Front and Back Sports Bras Fitness Workout Padded Buttery Soft Gym Bra Deep V-Neck Nylon High Support Yoga Bra OEM Supplier